Mould Release Agent-DYHT-81

Product characteristics

DY HT-81 is a water-based semi permanent mold release agent containing a special structured polymer resin. It has good adhesion to various metal molds and good chemical bonding with most mold materials, which can quickly form a uniform and dense thin film on the surface of the mold. The higher density and lower surface energy of this film effectively reduce the adhesion of the adhesive on the mold, and the release agent product itself will not transfer to the molded object, improving the appearance quality of the product.

Product use

Firstly, the mold should be thoroughly cleaned and it is recommended to use spray coating. For the first spraying, the release agent should be evenly sprayed 2-3 times on the hot mold and cured for a period of time. The longer the drying time and the higher the tempera- ture, the more durable and effective the release film formed will be. At the same time, apply or spray the DYHT-81 product on the surface of the product embryo for the first 3 to 6 times to ensure that the mold release agent is fully in contact with the mold. After these operating procedures are completed, normal production can begin. In the future, the vulcanization process only needs to be sprayed once every few intervals and cured for a period of time.

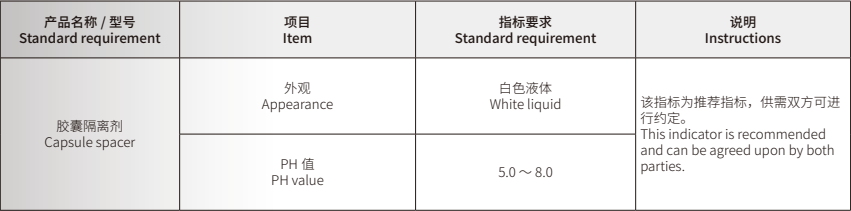

Technical index